1st compounding factoryProduction department

| Main products | Produces epoxy, silicone, and acrylic resins. |

|---|---|

| production amount | FY2023 1,700t 1,800t expected in FY2024 |

| production machine | 15L~5000L total 10 machines |

| Products filling range | 0.5㎏〜300㎏ |

2nd compounding factoryProduction department

| Main products | Produces epoxy and urethane resins. |

|---|---|

| production amount | FY2023 1,900t 2,000t expected in FY2024 |

| production machine | 350L~5,000L total 7 machines |

| Products filling range | 0.5㎏〜300㎏ |

3rd compounding factoryProduction department

| Main products | Produces epoxy and urethane resins. |

|---|---|

| production amount | FY2023 4,500t 4,800t expected in FY2024 |

| production machine | 800L~1,600L total 8 machines |

| Products filling range | 0.5㎏〜300㎏ |

Reaction factoryProduction department

| Main products | Produces epoxy and urethane resins. |

|---|---|

| production amount | FY2023 3,000t 3,100t expected in FY2024 |

| production machine | 800L to 3,500L total 7 machines + 250L solvent recycling pot |

| Products filling range | 0.5㎏~220㎏ |

clean roomProduction department

| Main products | Produces epoxy, silicone, and acrylic resins. |

|---|---|

| production amount | FY2023 48t 50t expected in 2024 |

| production machine | 5L to 250L total 7 machines |

| Products filling range | 8g~20㎏ |

Cargo handling tent in front of the automatic warehouse and auxiliary materials buildingBusiness department

-

Automatic warehouse

This automatic multi-level warehouse is capable of handling hazardous materials and achieves high-precision inventory management in conjunction with the core system. The system allows real-time monitoring of the status of incoming and outgoing shipments, enabling efficient operation.

The warehouse is operated with 8 rows of rack lanes, and 4 stacker cranes. The total capacity of the pallets is 1,016.

The cold area consists of 2 rows. It can accommodate 236 pallets. Maximum load weight per1 pallet is 1,200 kg. -

Cargo handling tent in front of the auxiliary materials building

It is a large cargo handling tent of 10 m high with an area of approximately 500 square meters.

This heavy truck yard can load and unload the racks of four heavy trucks at the same time and can be used for all kinds of scenes, such as export packaging work, in addition to cargo handling work.

Auxiliary materials buildingBusiness department

-

Auxiliary material building exterior

-

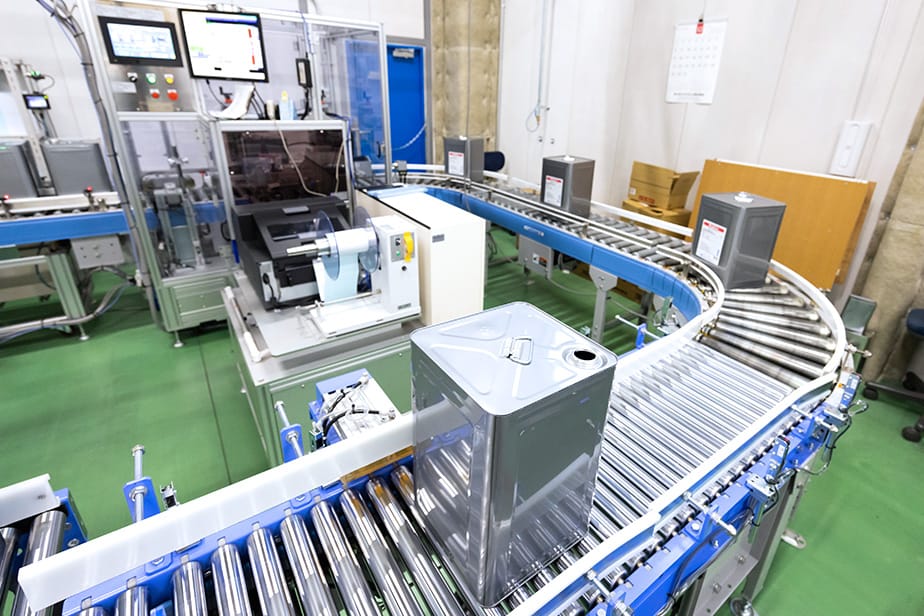

Auto parel rack

Auto parel rack is a fully automatic warehouse dedicated to raw materials. The configuration with AC power mollers and right-angle transfer machines and software control realize efficient operation.

By linking with the core system and utilizing barcode technology, it is possible to track and manage raw material information in real time. In addition, AI function automatically determines the optimum storage location according to the frequency of incoming and outgoing stock. Auto parel rack is the latest automatic warehouse that is one step ahead.

-

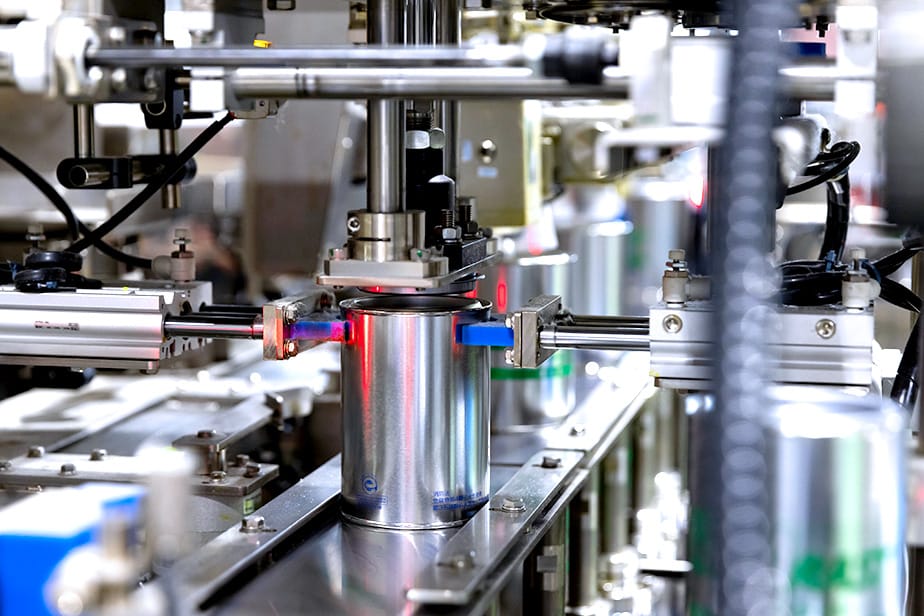

Automatic labeling machine

Printer auto labeler and fully automatic labeling machine with camera detection are Sanyu Rec original equipment.

Reading dedicated QR codes connects with the core system, and it is consistent from issuing labels to checking with the camera and auto-pasting labels.The camera sensor also accurately detects the position of the label and whether it is attached or not. Anyone can easily operate it, and it achieves high-precision labeling without work errors.

Packing buildingBusiness department

-

Industrial robot

The palletizer robot installed in the distribution packaging area loads the products flowing from line 2 of the packaging process onto the pallet. It does the work much faster and more accurately than by hand.

The introduction of this palletizer has reduced the workload, increased efficiency, and reduced labor. We have also succeeded in significantly reducing overtime hours.It is a pioneering facility that will drive Sanyu Rec's work style reform and is now an indispensable part of the company.